Electron Probe Micro Analyser Laboratory (EPMA Lab)

Overview

The Electron Probe Micro Analyser Laboratory (EPMA Lab) is a partner of the C4G Consortium (Collaboratory for Geosciences – the national research infrastructure for Geosciences), also member of the European Plate Observing System (EPOS). The EPMA Lab is registered in the MERIL database, an inventory of European Research Infrastructures of excellence, with supranational relevance in all scientific domains. Currently, the EPMA Lab scientific coordination is assigned to António Mateus, assisted by the chief operator and Lab manager Pedro Celestino Rodrigues.

The primary purpose of the electron microprobe is to generate quantitative and qualitative chemical analyses of any material stable under the electron beam in high vacuum conditions. Such materials include minerals, glasses, ceramics, and metals/alloys. Thus, the main scientific domain is Mineral Science (here including copious intertwines with Petrology, Geochemistry and Metallogeny), although easily connecting interfaces with the field of Materials Science and Engineering.

The EPMA Lab is quite active and productive. In routine it provides support for all the researchers and post-graduate students interested in mineral chemistry data, mostly affiliated with the Geology Department of FCUL and the IDL’s RG3 and RG2, but also coming from other Portuguese research units/institutions (such as ICT-FCUP, Univ. Aveiro, IST, among others). Although fewer in number, it is also worth mentioning the use of the Lab by several foreign researchers under protocols established via C4G or through international consortia that support various research projects in which IDL is a partner. The EPMA lab was part of the European Electron and X-Ray Imaging Infrastructure (EXCITE Network) from 2021 to 2024 providing trans-national access (in-site and remote) to the lab by foreign researchers, including from outside Europe. In addition to the activities carried out by the interested parties themselves, the EPMA Lab provides analytical services upon request to companies. The total number of Lab users varies, but the average record for the last 3 years points to: 18 MSc students, 12 PhD students, 11 IDL researchers, 6 foreigner researchers. Summing up, the EPMA Lab is a central analytical infrastructure that assists several lines of (fundamental and applied) research (≈50%) and custom services (≈5-10%), being vital to post-graduate training at FCUL (≈40%); in this overall appraisal, the weight of graduate training is residual (<5%) and mostly confined to the “Project” curricular unit.

The financial costs with the EPMA Lab are high, especially those related to annual maintenance and replacement of internal components (due to wear or damage) or externally coupled components (cooling system, gas supply circuits, monitors, computers, etc.). The number of technical repairs tends to increase with the age of the equipment, being necessary to maintain a stable fund of ca. 15-20 k€ per year to guarantee the operability of the entire infrastructure. There are also (lower) costs with consumables, namely gases and filaments. A significant part of the funds required to support EPMA Lab result from research (national and European) projects and service provision requested by companies, the latter being more discontinuous. Financial support via specific IDL funds is, therefore, critical when, circumstantially, the main sources reveal greater weakness.

Infrastructure

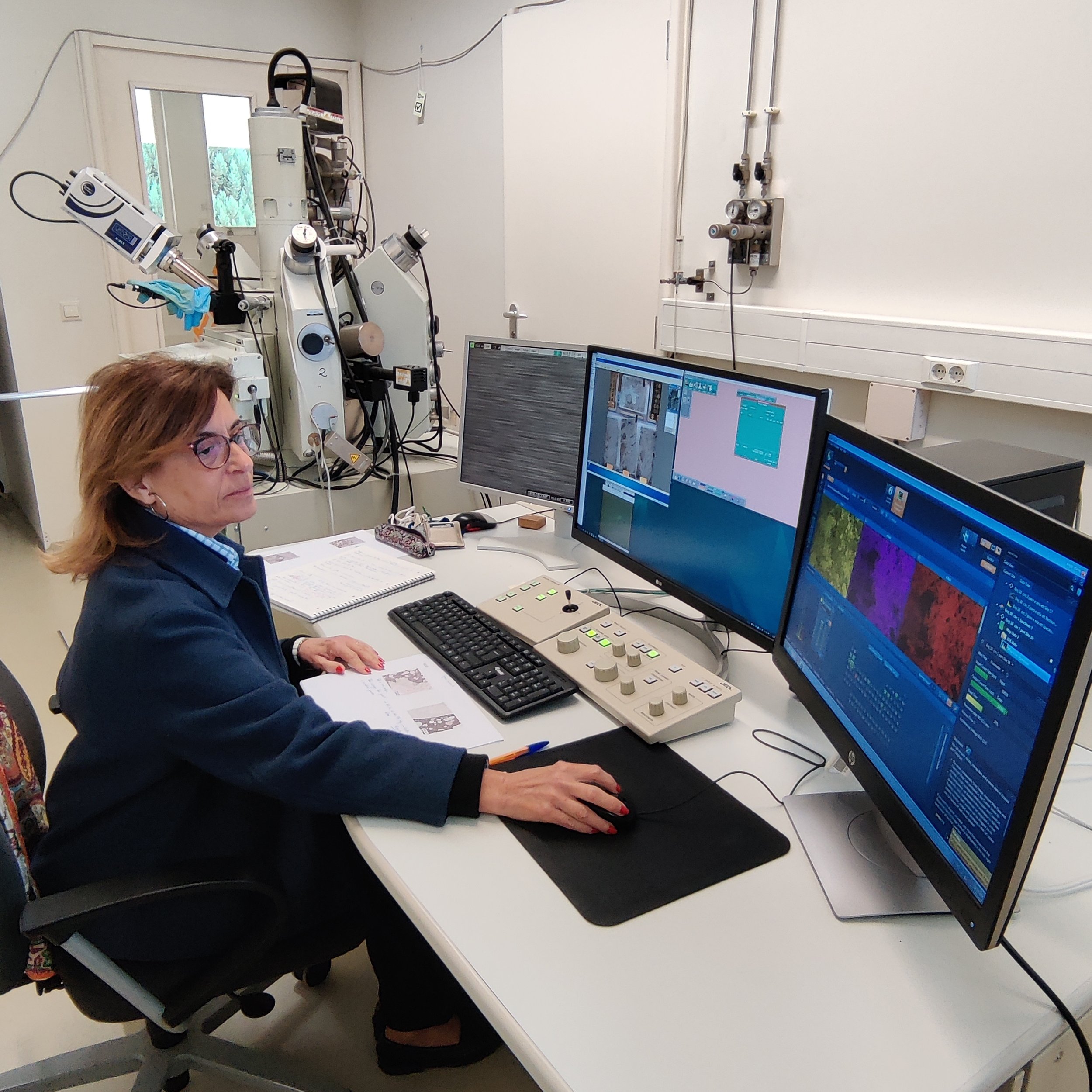

The EPMA Lab, sited in the FCUL Campus, is part of a series of lab-infrastructures assigned to the compositional characterization of geological materials, which are distributed across the 1st floor of the C6 building (Geology Department).

The EPMA Lab has one dedicated specialised technician (Pedro Celestino Rodrigues) and uses a JEOL JXA 8200 electron microprobe equipped with an EDS spectrometer, four WDS spectrometers and eigth crystals of six types (TAP, LDE2, LIF, LIFH, PETH and PETJ), besides secondary and backscattered electron detectors. The equipment is controlled by its own electronic processors, but routinely remote-controlled by a Sun Workstation, to which a PC is associated for data export convenience. The microprobe control software and command software installed on the workstation allow a high degree of automation in obtaining analytical and image data. The main appliance is cooled through a closed-circuit water circulation system and connected to an adequate voltage stabiliser to prevent damages caused by sudden failures of the main electrical supply.

The EPMA Lab also has a carbon evaporator (BALTEC CED 030) for covering the samples to be analysed with graphite. In addition, a wide spectrum of standards (some recently acquired) is available at the EPMA Lab, embracing minerals, metals, and synthetic materials.

Routinely, the EPMA Lab generates qualitative chemical analyses (~1-3 μm3) of elements with Z>6, quantitative chemical analyses (~1-3 μm3) of elements with Z>6, compositional maps (backscattered electrons), concentration maps of specific elements, and images of secondary electrons. The default sample configuration for EPMA is a flat, micro-polished surface that is infinitely thick to keV electrons, corresponding to materials with a thickness greater than ≈25 microns. Polished thin sections and bulk-cast epoxy mounts are typically used. Analysis of bulk materials that have been polished and graphite-coated is the default scenario for EPMA; the software correction and virtually all instructions pertain to that application. Other geometries require different sample preparation and further involvement from the user to obtain corrected results.

Quantitative data are obtained with high precision and accuracy, due to the application of an unpublished algorithm to the standardisation procedures of the instrument, which minimises uncontrolled factors affecting the usual standardisation procedures. In addition, special in-house software can be used to automatically reduce large amounts of analytical data.

Main highlights

In the last five years, the analytical results provided by the EPMA Lab supported several dozen articles published in different specialized journals (>70), technical reports for companies (10), master's (35) and doctoral theses (20, already defended or in advanced progress stages). These results reflect distinct applications in the following scientific domains (non-exhaustive list): mineralogy, petrology, metallogeny, sedimentology, material sciences, environmental geology, solid state chemistry, archaeometry. The main focus of the analytical activity carried out was on: (i) the identification and determination of the chemical composition of unknown mineral phases; (ii) the compositional growth zonation or other chemical features aiming at thermobarometric or other intensive variables appraisals based on mineral chemistry, assessments on partition coefficients, and studies on reaction mechanisms between mineral phases or resulting from fluid/mineral interactions; (iii) micro and crypto-textures due to chemical decomposition processes involving mineral (or other solid) phases; and (iv) comprehensive characterisation of ore-forming phases and of mineral phases which composition is sensitive to mineralising processes, therefore potentially useful in the design of innovative mineral exploration surveys.

Many of the scientific contributions resulting from research supported by data obtained at the EPMA Lab (together with other factual elements) have clear societal relevance. Among the various studies completed, it should be mentioned those that have been carried out on a recurring basis dealing with: (i) the ore-forming processes and subsequent contributions to design of innovative geochemical exploration surveys; (ii) the characterization of mineral phases forming different types of ores (including those classified as critical, i.e. with high economic importance and high likelihood of supply disruption or shortage) and implications for the optimization of processes related to the production, treatment and benefiting of mineral concentrates (impacting the metallurgical processing lines); and (iii) chemical reactivity of concrete and its degradation in different contexts. Most of these studies have been developed in partnerships with companies in common research projects, sometimes complemented with specific service requests.

Future prospects

The current configuration of the EPMA Lab allows it to respond satisfactorily to current and short-term needs if the focus of the research work carried out so far is maintained. In the medium-long term, however, the existing JEOL JXA 8200 microprobe will hardly be able to guarantee innovative and competitive results, not only because the equipment will greatly exceed its useful life (requiring higher investments in repairs whenever possible, i.e. when components to replace are still available), but also because it will not allow technological upgrades (guaranteeing improvements in analytical capacity and resolution, as well as the opening of new lines of investigation in Mineral Science). In fact, aiming to expand the spectrum of analyses/services provided by EPMA Lab, we recently evaluated the possibility of coupling a cathodoluminescence and a fifth (ultra-high resolution) spectrometer to the JEOL JXA 8200 microprobe. The latter, a soft X-ray emission spectrometer (SXES), would significantly increase our analytical capacity, allowing the measurement of light elements (e.g., Li, B, N) in minerals and other materials. We found, however, that the JEOL JXA 8200 microprobe is no longer compatible with the SXES or the cathodoluminescence detectors available on the market, given its age. In fact, the JEOL JXA 8200 electronic microprobe in use was acquired in 2007, after a successful application to a national scientific infrastructures program supported by the Foundation for Science and Technology. Seventeen years have passed, and the JEOL JXA 8200 microprobe useful life is approaching the end, with no upgrades of any kind possible, which is critical for future forecasts.

Considering the type of analyses performed in the EPMA Lab, useful or crucial results could be potentially generated for several technical (societal relevant) domains, such as: (i) quality control of materials; (ii) decomposition or alteration of materials; (iii) studies of materials related to the restoration or conservation of monuments and works of art; (iv) fatigue of materials (metallic alloys); (v) forensic investigation; and (vi) phase analysis of machine parts or materials. These are some of the avenues that may enhance the societal impact of this lab facility, exploring the service portfolio and ensuring complementary sources of financing. However, to increase competitiveness, ensuring the quality of analytical results as well, it will be necessary to invest in peripheral components that, coupled to the electron microprobe, can provide additional elements to those currently possible to obtain.