Thin & Polished Sections Laboratory (LABLAPOL)

Overview

The Thin & Polished Sections Lab (LABLAPOL) was set up in 1987 as a facility dedicated to providing services, having continuously performed these functions until the present. The gradual degradation of the original equipment led to evident losses in efficiency of the lab unit in recent years, something that was only possible to definitively overcome at the end of 2022 with the purchase of new instruments (see below). Currently, the LABLAPOL scientific coordination is assigned to António Mateus, assisted by the chief operator and Lab manager Sofia Rodrigues.

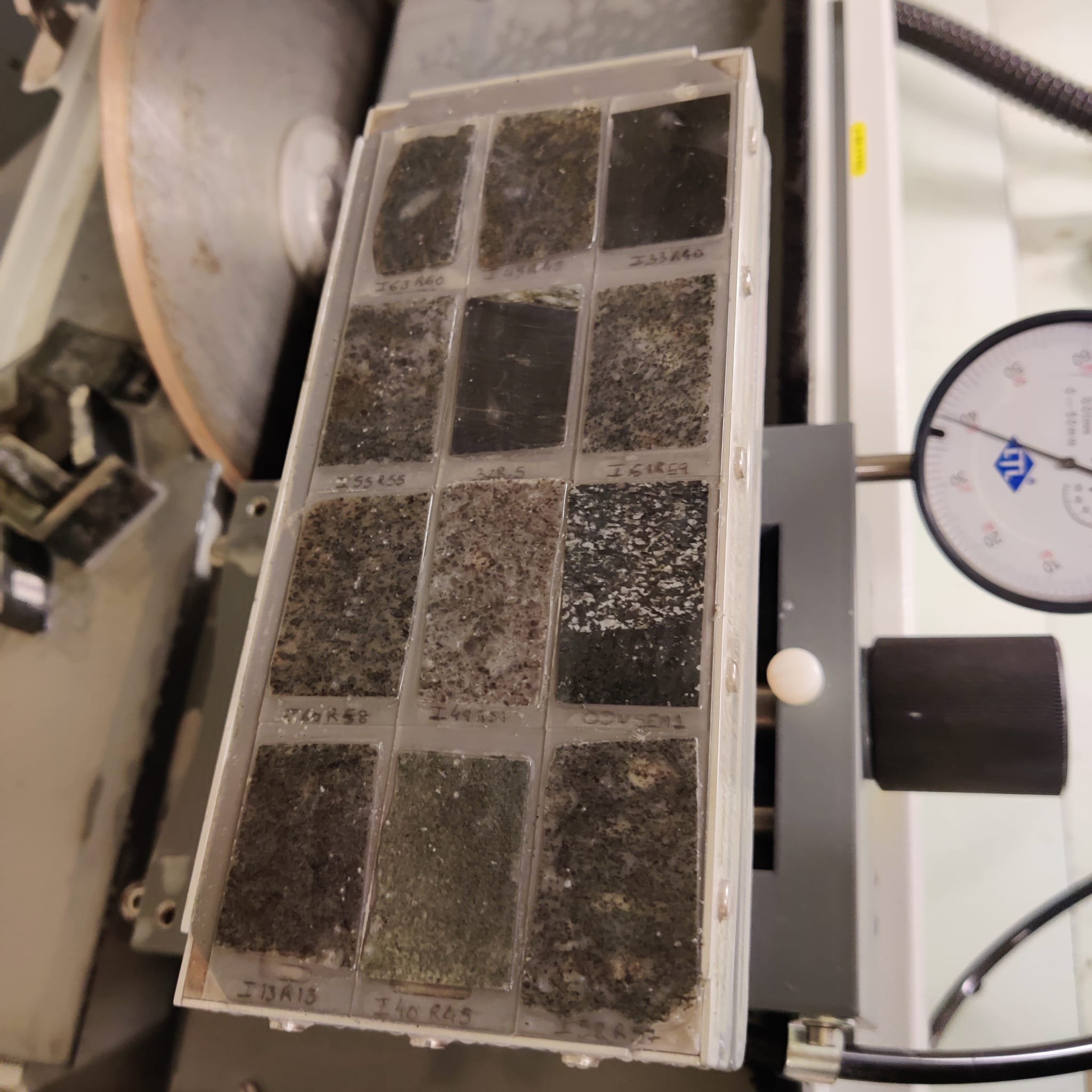

The main activity in LABLAPOLs involves the manufacture of thin sections (simple or polished, 30 µm thick) of rocks, aggregates or other materials that can be bonded with resins, aiming for their characterisation in transmitted and reflected light microscopy, as well as in electron microscopy. Other tasks carried out in LABLAPOL include: (i) the production of bi-polished surfaces (generally 80 µm thick) of rocks for studies of fluid inclusions or melt inclusions; (ii) the polishing of rock surfaces for various studies; and (iii) the completing of impregnations with epoxy resins.

The LABLAPOL outputs are the mainstay of all research activities aiming any kind of petrographic (mineralogical and textural) characterisation of rocks, aggregates, concrete, slag, etc. These outputs are mandatory in numerous lines of fundamental and applied research, being therefore unavoidable in most of the research projects involving people from the Geology Department of FCUL and the IDL’s RG3 and RG2, as well as in a high number of research topics supporting MSc and PhD theses. The LABLAPOL outputs are quite competitive and, because there are few units in Portugal producing (top quality) thin sections, they are an added value in services provision (for other research entities or companies). The work carried out at LABLAPOL is also essential for the regular functioning of all curricular units from the 1st and 2nd study cycle programmes in Geology that, in their practical modules, use optical microscopy.

The allocation of work carried out in LABLAPOL to each application domain varies greatly from year to year. However, the track record (existing since 1989), it is reasonable to assign the following percentage ranges to each application domain: 50-60% for fundamental and applied research (supported by research projects or independent service contracts); 20% for postgraduate course units; 15-20% for undergraduate course units; and 5-10% for the provision of specific services.

The LABLAPOL's average annual costs vary between €5k and €10k, depending on the number of repairs of components subject to significant wear, in addition to fluctuations in the values allocated to the various types of consumables (abrasives, glass, lubricating oils, epoxy resins, diamond pastes, polishing cloths, etc.). The funds required to support LABLAPOL result from research (national and European) projects and services requested by external entities.

Infrastructure

The LABLAPOL, sited in the FCUL Campus, is part of a series of lab-infrastructures assigned to the basic preparation of geological materials for subsequent studies, which are distributed across the ground floor of the C6 building (Geology Department).

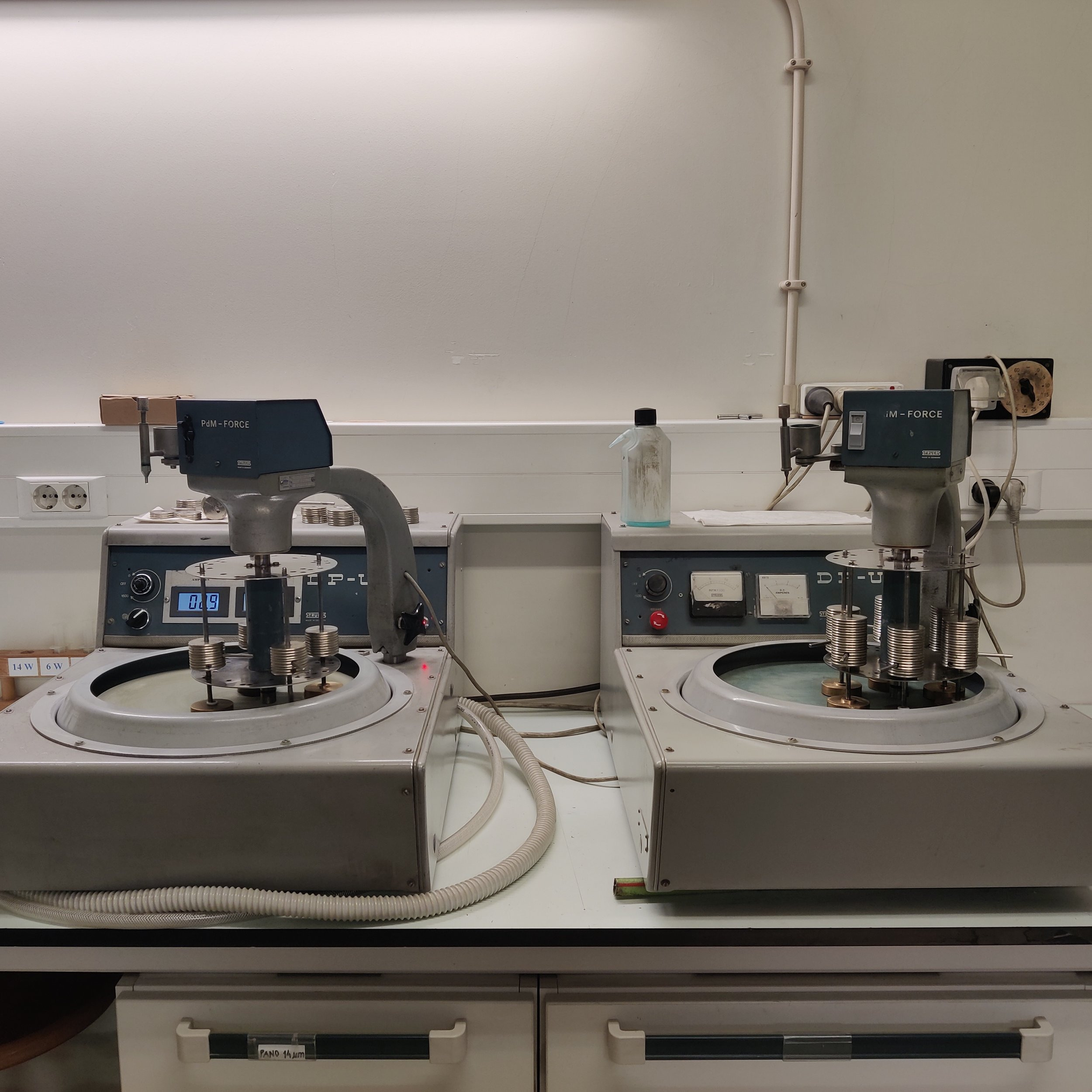

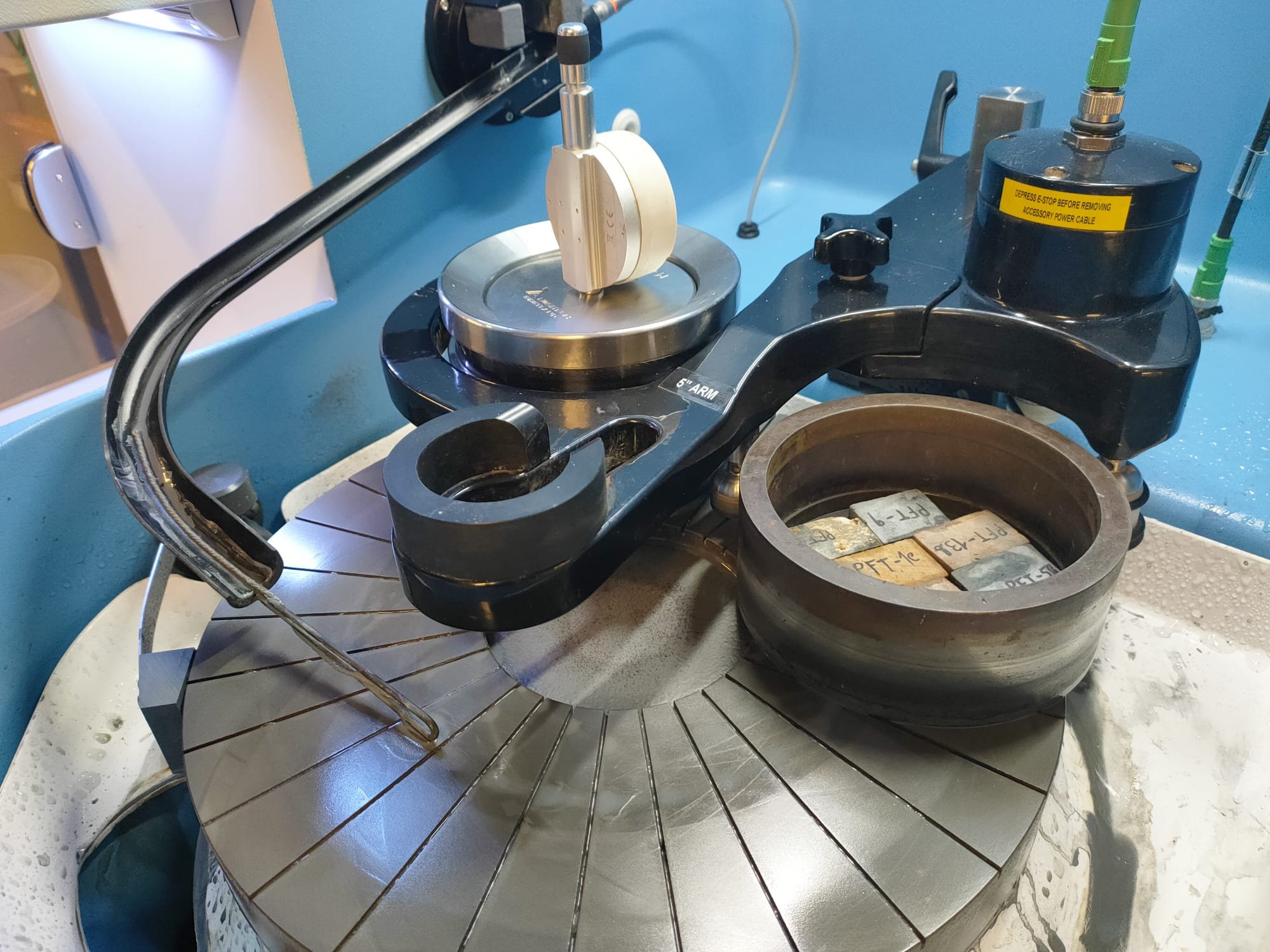

The LABLAPOL Lab has one dedicated specialised technician (Sofia Rodrigues) and uses in routine a GTS1 (Logitech) Thin Section Cut-off Trim Saw and a PM6 (Logitech) Precision Lapping Polishing Machine. Both devices, representing a significant jump in quality and productivity, were purchased by a joint investment between IDL (40%) and funds collected from past service provisions (60%). The LABLAPOL has heating plates with a pressure system that allows 26 mounted sections to be glued at once. The polishing procedures are done with two DP-U2 STRUERS instruments. The PM6 equipment includes a driven jig roller, WG power connection, Bluetooth connectivity for auto-plate flatness monitor (and auto-lap software upgrade), and an abrasive auto-feed cylinder (220-240 V 50 Hz). The GTS1 equipment is a compact, bench-top unit that allows automatic operation during the cutting of bulk rocks and the thinning of mounted sections. Furthermore, it includes a support system enabling the simultaneous cutting of 12 mounted samples. It offers several advantages over other saws, in particular the variable speed linear drive system and feed rate monitor allow the operator to control the rate at which the samples move through the cutting process. This avoids many of the problems associated with gravity-fed systems, such as material shattering; samples can be repeatedly trimmed to as thin as 200 microns, saving lapping time and increasing productivity.

Main highlights

In the last five years, the outputs of LABLAPOL supported a high number of research projects and services contracts, besides the research activities of many postgraduate students. It is hard to provide absolute figures about the real impact of these outputs, but for sure they are by large reflected in several dozens of papers published, many MSc and PhD (completed and ongoing) theses, and numerous technical reports for companies. As already mentioned, LABLAPOL can be perceived as a critical and transversal facility for all research activities that involve the characterisation of geological materials. The relevance of LABLAPOL is not always properly valued, but when this unit was closed for many months (firstly due to the lack of dedicated staff, then to the breakdown of the old equipment), many people realised for the first time its added value, being forced to contract services from the few entities that, in Portugal and abroad, could provide them.

In the last 20 months, 330 thin sections, 800 thin-polished sections and 15 polished surfaces were produced in LABLAPOL, which assisted the research work of 14 MSc students, 8 PhD students, 7 IDL researchers and 2 foreigner researchers, in addition to 4 external service requests.

Future prospects

The recent update of the equipment that supports LABLAPOL makes this unit one of the most advanced of its kind in the Iberian Peninsula that is also open to external service requests. Assuming that current operating conditions are maintained, LABLAPOL will be able to substantially increase its performance in future, addressing the needs of research projects and applications of external entities. In what concerns the latter requests, it should be noted that the supply/demand imbalance is very high in some specific market niches, such as: (i) the production of thin (polished) sections or other specific rock-surfaces to support various requests arising from entities linked to the mining sector (metallic ores, ornamental stones, industrial rocks and minerals); (ii) petrographic analysis of concrete and (natural or artificial/crushed) aggregates; (iii) slag characterisation seeking for its reuse or recycling; (iv) examination of degraded and replacement materials in built-heritage components.

The LABLAPOL support for classes, MSc and PhD theses should remain relatively constant over time.

Contact Person

Sofia Rodrigues

Address

FCUL, Campus